Smart Specialisation

F&FG has partnered with the Latrobe Valley Authority to deliver the food and fibre stream of the Gippsland Smart Specialisation Strategy (GS3).

The GS3 is a dynamic, place-based regional development initiative that builds on our region’s key strengths by fostering innovation for long-term, sustainable economic and social advantage.

These increases in advantage are achieved by proactively and collaboratively exploring innovative industry opportunities for the Gippsland region with stakeholders from across industry, government, education and/or research, and community sectors. This approach of collaborative co-design ensures that opportunities are assessed from multiple viewpoints, are backed by data, and have the support required to ensure their success.

The food and fibre stream of the GS3 is currently defining, and delivering on, multiple innovation opportunities to drive regional competitive advantage.

Sustainable Emerging Commodities - Insects & Seaweed

The Latest News in Smart Specialisation

Want to get involved in the development of any of the opportunities outlined?

We’d love to hear from you! We welcome input from any interested parties and look forward to hearing from you about how you'd like to contribute to the success of our region.

Ben Gebert, Chief Executive Officer

e: ben.gebert@foodandfibregippsland.com.au | m: 0437 800 781

Elena Nauta, Project Manager - Regional Industry Innovation

e: elena.nauta@foodandfibregippsland.com.au

Advanced Vegetable Processing

Gippsland grows a highly diverse range of vegetables and greens across its broad geographic footprint, comprising 25% of the state of Victoria's overall vegetable production. Many of these vegetables are sold direct to fresh markets, requiring producers to meet stringent specification levels on size, weight and appearance.

What happens to the produce that doesn't meet specification?

Gippsland's growers generally sell this produce into other markets such as the processing market, for livestock feed and to local fresh markets that aren't so concerned about things like a carrot having two legs. Some of this produce, however, becomes the non-consumed fraction - a term used for produce that never reaches the intended consumer. This fraction accounts for nearly 30% of production, and is sometimes ploughed into the ground, composted or lost to landfill.

The Advanced Vegetable Processing (AVP) opportunity stream has been working with Gippsland growers, researchers, processors, government and the community to develop the concept for a local facility that would utilise this non-consumed fraction and process it into high-value ingredients and nutraceutical products (a market worth hundreds of billions of dollars across the Asia-Pacific region alone).

A business case for the AVP has been developed and F&FG is working to socialise this opportunity with government agencies and investors with the aim of having a bricks and mortar facility established in the near future.

Carbon Economies

Carbon, one of earth's most abundant elements, is a key building block found in our soils, plants and living creatures. It also binds with oxygen to create one of our most-commonly emitted greenhouse gases, Carbon Dioxide (CO²).

CO² emissions are an output of many consumer, organic and industrial processes, which when released trap heat within the earth's atmosphere. Climate change outcomes are commonly attributed to the continued emission of high levels of CO² which, if left unchecked, will continue to detrimentally impact food and fibre production systems; maritime environments; and our earth's liveability.

Carbon sequestration, the process of removing this atmospheric carbon and storing it, is achievable through food and fibre production. Plants (on land and at sea) pull carbon from the atmosphere and store it within themselves and the soil. So, while Gippsland's thriving food and fibre production ecosystem is already playing a role in sequestering carbon, it's not currently being measured.

The GS3's Carbon Economies project proposes to:

Undertake a carbon auditing exercise across the Gippsland region to establish carbon assets and liabilities

Determine the potential for a combined regional carbon market that allows net emitters to offset their emissions, and for net reducers (those who are sequestering more carbon than they're emitting) to trade the carbon they're sequestering.

Create a regional ecosystem that incentivises overall reductions in CO² emissions.

Circular Economies

The Gippsland region is one of Australia’s most highly diversified production regions, producing everything from milk to mushrooms and beef to broccoli. Our region’s produce is renowned for its quality and green production methods. Despite this, it is estimated that nearly 30% of all produce grown within our food and fibre production systems is lost or wasted prior to reaching the farm gate (the non-consumed fraction). This is not a Gippsland-specific figure but applies to production systems the world over.

Our producers don't want to see the fruits (and vegetables) of their labour not reaching their end consumer, however it's often challenging and time consuming to find a market for produce that doesn't fit within specifications.

The Circular Economies Marketplace opportunity was suggested by F&FG stakeholders as a way to easily link producers who have surplus produce or produce that they can't easily move, with buyers who might have a use for it. Such a platform would cut down on waste, provide new revenue streams for sellers, provide buyers with a product that they may normally have difficulty in finding, and contribute to the improvement of our region's sustainability.

For information about the Gippsland Circular Economy Hub, visit the dedicated webpage here.

Collective Craft Malting

Beer and spirits. Two products that Gippsland's breweries and distilleries market locally, nationally and to the world. These products are often used to tell the story of the Gippsland region and the businesses that produce them. Their key ingredient, however, isn't locally available - something that our region's brewers and distillers would like to see change.

The Collective Craft Malting facility opportunity aims to process locally grown grain into the key building block for beers and distilled beverages: malt. Despite not being recognised for it, Gippsland grows a considerable amount of grain. Parts of the East are renowned for their world-leading corn varieties (among others) whereas cereal growers can be commonly found throughout both Central and East Gippsland. Nearly all of this grain is sold to stock feed, a commodity that commands a lower price than "malting" grade grain. This is despite trial malting batches undertaken to inform the Collective Craft Malting Facility opportunity indicating that Gippsland grown cereals are certainly suitable for malting.

Not only would the facility provide our region's brewers and distillers with a locally-grown and processed product, bolstering their regional provenance story, but it would create new industry; provide alternative markets for growers to sell to; employ locals in a field that's experiencing high levels of growth; and encourage new thinking.

Sailor's Grave Brewing in East Gippsland, have made space for a facility to be located within their Dune Town precinct - a brewery and experiential tourism destination - located between Marlo and Cape Conran. The GS3 team and stakeholders are working on establishing a pilot malting facility with a social enterprise structure that will contribute considerably more than just an important ingredient for the Gippsland region.

Sustainable Emerging Commodities

The need for sustainable food sources has never been greater.

The United Nations Food and Agriculture Organisation has predicted that the population of the world will expand to over 9 billion people by the year 2050, creating significant environmental, nutritional and food security challenges that traditional agricultural practice will have difficulty meeting.

There are some food products, however, that can feed populations while benefiting the environment.

Cue seaweed and insects.

Seaweed

Whilst sometimes annoying to encounter whilst out for a swim, is an extremely versatile food and bioprocessing ingredient. Already a key ingredient in thickeners and gelling agents in the kitchen, certain varieties can be processed into environmentally-friendly "bioplastics", fertilisers, even fuel sources for energy production or combustion.

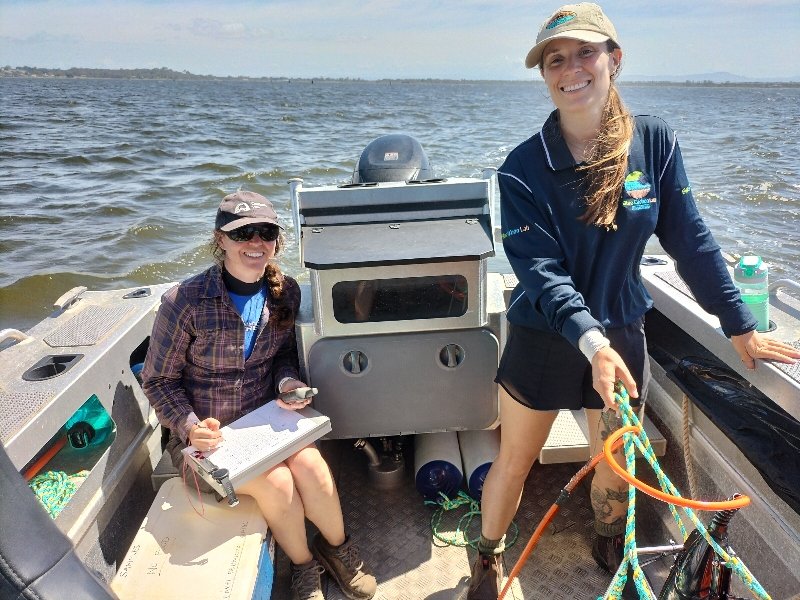

Feed additives made from seaweed are currently being trialled by a number of organisations for their ability to reduce methane emissions in cattle and other ruminant animals, and are showing extremely positive results. With Gippsland's circa 600kms of coastline and inshore lake systems, a local seaweed industry may not only spur on valuable processing opportunities, but create significant environmental benefits for marine life and carbon sequestration - something seaweed does at a faster rate than any other plant species.

Insects

Insects are the world's most abundant creatures. Certain varieties are also, pound for pound, the most efficient of all protein sources at converting their feed and water inputs into useable, consumable protein. The edible portion of these critters is also considerably higher than any of our traditional protein sources, making them an attractive (albeit unfamiliar) prospect as a complimentary protein provider.

Food aside, insects are also a phenomenal feed source for animals. The larvae of the black soldier fly can quickly convert organic waste that has little other application into body mass suitable for processing into fish or other agricultural feed with high nutritional value.

Work is underway to determine how these sustainable emerging commodities may be grown and/or processed in Gippsland, alongside engagement with Traditional Owners to ensure enduring access and benefit sharing agreements.

Vertical Farming

Nothing conjures visions of science fiction more than controlled environment agriculture, better known as vertical farming. It is, however, a reality, and an exciting new way of both growing valuable food items and researching new cultivation methods.

Most commonly, vertical farming uses hydroponics, where plants are grown in vertically stacked beds of inert material, with the roots fed via reservoirs of water with the required nutrients dissolved within. LED lighting systems provide the energy, run by automated artificial intelligence (AI) software that also controls temperature, humidity, and CO2.

Renewable energy sources such as geothermal or bioenergy may be used in these systems, providing a sustainable controlled environment. This controlled environment has several advantages; vertical farming produces leafy greens in higher yields, with less time to harvest, while using 95% less water than traditional agriculture, without the need for pesticides, fungicides, or herbicides.

Vertical farms come in a wide variety of designs, including repurposed buildings, custom built models, or modular kits of varying sizes; different models can complement existing agricultural production as integrated production facilities or stand-alone systems. This versatility in potential applications makes vertical farming a valuable potential addition to Gippsland agriculture, which can potentially complement and increase Gippsland’s profile as a national leader in food research and production.

Industrial Hemp

Industrial hemp is a particular class of the Cannabis sativa plant grown for food, fibre or medicinal purposes that contains extremely low to zero concentration of the psychoactive compound tetrahydrocannabinol (THC) traditionally associated with recreational cannabis use.

Hemp is one of the most versatile bioresources on the planet, one almost forgotten in our modern, plastic laden world. In 1938, Popular Mechanics magazine touted hemp as the next ‘billion-dollar crop’, however the scientific advancements of the 20th century led industry away from natural fibres. The growing awareness of climate change and the need for sustainable economies have driven renewed global demand for hemp and hemp-derived products.

Hemp has three useful components – the seed, external fibres, and inner hemp hurd (short fibres). Hemp seed has a variety of food (high in omega 3), skincare and cosmetic applications, hemp fibres can be used in textiles (including clothing), paper, and rope, whilst the inner hurd may be used as animal bedding, construction materials, hempcrete, moulding, and sound proofing. Global research is also under way investigating hemp as a biodegradable plastic replacement and biofuel.

Hemp cultivation and processing has been identified as a particularly valuable potential opportunity for the Gippsland region. Various areas in Gippsland may be suited to commercial hemp fibre production and processing due to existing land use, a history of horticulture production, availability of irrigated water, relative proximity to processing facilities and low opportunity cost compared with other regions.

The latest news in Smart Specialisation

Check out the latest news in our Smart Specialisation Program